Science fiction becomes reality; 3-D printing uses expand

November 1, 2018

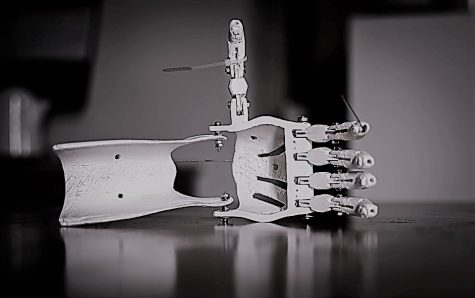

Thirty years ago, when the movie Transformer was released, alien robots self generating damaged limbs, skulls, and brains was considered science fiction. Generating customized limbs and brains is now a reality, not only for alien robots in movies. 3D printing involves bringing to life a solid 3D object from a digital file. The object is created by laying down successive layers of material until the object is completed. Plastics, metal alloys, concrete, and even living tissue can be used as mediums. The fast growing industry is expected to increase in value from $12.8 billion in 2018 to over $21 billion by 2020 (CBSNews).

Prosthetics and implants, difficult to custom design by hand, now have the capability for complete personalization. Layers of living cells with the patient’s DNA are deposited into the print medium to create the intended prosthetic/implant.

Patches, a nine year old dachshund suffering from a life threatening tumor on her skull, made full use of the new technology. Seventy percent of Patches’ skull needed to be removed. In order to replace the missing seventy percent, a custom made skull made from titanium was 3D printed.

3D printers can be used to replace not only missing parts of dog skulls but also broken parts of dirtbikes. Steven Caldwell explains “a plastic washer broke, that needed an adapter” on his dirtbike. Steven used his own 3D printer at home to design a replacement.

The National Aeronautics and Space Administration (NASA) has been using 3D printing technology to perfect the shuttle shields. While perfecting the shielding, NASA has also been exploring the possibility of turning extraterrestrial soil into printable parts to use as a new medium.

Fashionistas, including Danit Peleg have been using the technology to design jackets. Usine a computer software, and then printing the design using a 3D printer to create jackets. The new industry allows fashion lovers to custom design their own jacket, have it printed, and delivered in just a few clicks.

The typical view of construction workers teetering on top of the skeleton of a house is being revolutionized in China. There has been experimentation with 3D printing houses using recycled materials. Some houses are printed separately and later assembled. Other construction sites have 3D printers mounted to cables, with drones monitoring the process.

While 3D printing is useful worldwide, it can be difficult in a classroom setting. According to Mr. Tim Dougherty, “besides designing the object in CAD, the process of actually creating and printing them out is slow, and only a few students work can be printed.” Students in Dougherty’s class will be printing anything from a pair of dice they design to small prototypes of city buildings.

3D printing may require patience in a classroom setting. However, these 3D printers are still faster and more efficient than making the product by hand. Field Ready, a humanitarian organization assisting in Earthquake relief, uses their mobile 3D printer to print pipe replacements for broken water lines. With working pipes, Field Ready was able to provide an entire town with running water in a relatively short amount of time.